The common operating principle of all magnetic separators and the main purpose of magnetic filtration is to separate the steel particles from the filtered material.

Separators are constructed on the basis of neodymium or ferrite magnets. As magnetic filtration is required in many places and circumstances, there are many separator models adapted to various applications and needs.

Why is it worth, why is it necessary?

During manufacturing and processing procedures, there may be a risk of contamination of the production line with unwanted steel elements such as staples, filings, pieces of wire and many others. The source of contamination may take place both in inclusions in raw materials and semi-finished products, as well as in the logistic or technological process. The purpose and effect of magnetic separators is the effective and possibly easy-to-use separation of undesirable steel particles, protecting the line and the final product against their negative effects, such as damage to machines, downtime in the process or reputational losses.

Below you will find the most common examples of magnetic separator models from our offer.

Rotary separators

Rotary separators consist of magnetic cores rotated by an electric motor and enclosed in a dust-tight body. This solution is ideal for filtration of materials that tend to build residues or clogging. …

Magnetic rollers

Magnetic rollers are most commonly used at the end of conveyor belts as automatic filters for steel particles. Installed as a return drum of a conveyor belt, they hold ferromagnetic impurities, allowing them to "peel off" only when they are separated from the filtered material. …

Drum separators

Used for automatic filtration of loose medium and fine materials. Highly efficient devices that protect ex. technological machines against damage caused by steel impurities. Devices of this type are also very well suited for the recycling industry. …

Magnetic beams

Magnetic beams are smaller and lighter than plate separators. They are constructed on the basis of neodymium magnets. Despite their smaller volume, they generate very strong magnetic field. They are usually, but not always, used over belt conveyors. …

Plate separators

Plate separators are massive devices mounted above the conveyor belt. They are usually manufactured on the basis of ferrite magnets. They are characterised by a wide range of operation and resistance to high temperatures. …

Pressure flow separators

Suitable for separation of liquid and semi-liquid materials transported under high pressure. The operating pressure can reach up to 8 rods depending on the model. Through the magnetic rods in the separator flows the material to be purified, ensuring optimal magnetic contact and maximum filtration. …

Flow separators

Relatively simple models designed to filter ferrous impurities from liquids of different densities. Inside, there are magnetic rods to catch steel impurities. We manufacture devices for both food products, such as chocolate, milk and fruit preserves, and liquids for industrial use, such as fuels and coolants. …

Threshold separators

An extremely effective and yet very simple to apply type of separation. These devices are usually installed at the end of a conveyor belt. The material is moved by gravity and all unwanted steel impurities are stopped under the magnetic threshold(s). …

Conical separators

Conical separators, also known as cylindrical separators, are ideal for loose materials of medium weight. Metal impurities are trapped under protruding rings of the core inside the separator, on which magnetic energy is concentrated. …

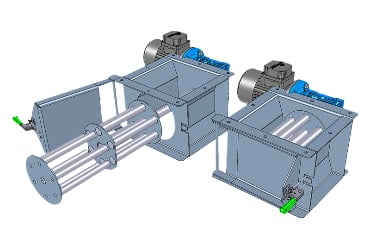

Drawer separators

They are characterised by extremely high efficiency and easy cleaning. In their dust-proof body they have shafts filled with neodymium magnets, which generate magnetic fields of high intensity and density. They easily capture the smallest metal particles, filings, iron oxides, spherical elements and other particles with low magnetic susceptibility. …