Magnetic rollers

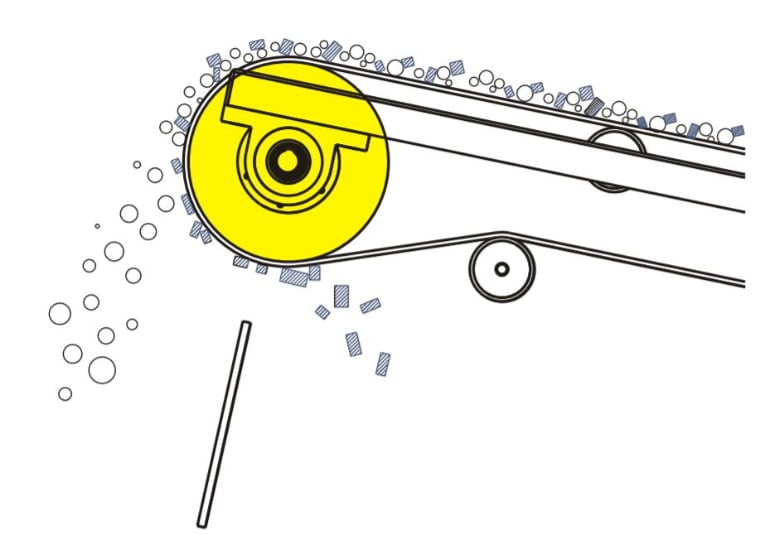

Also known as magnetic drum. They are used for automatic cleaning of loose materials, ex. granulate or pellets, moving along the conveyor belt from ferromagnetic impurities. They are adapted to work in a continuous operation.

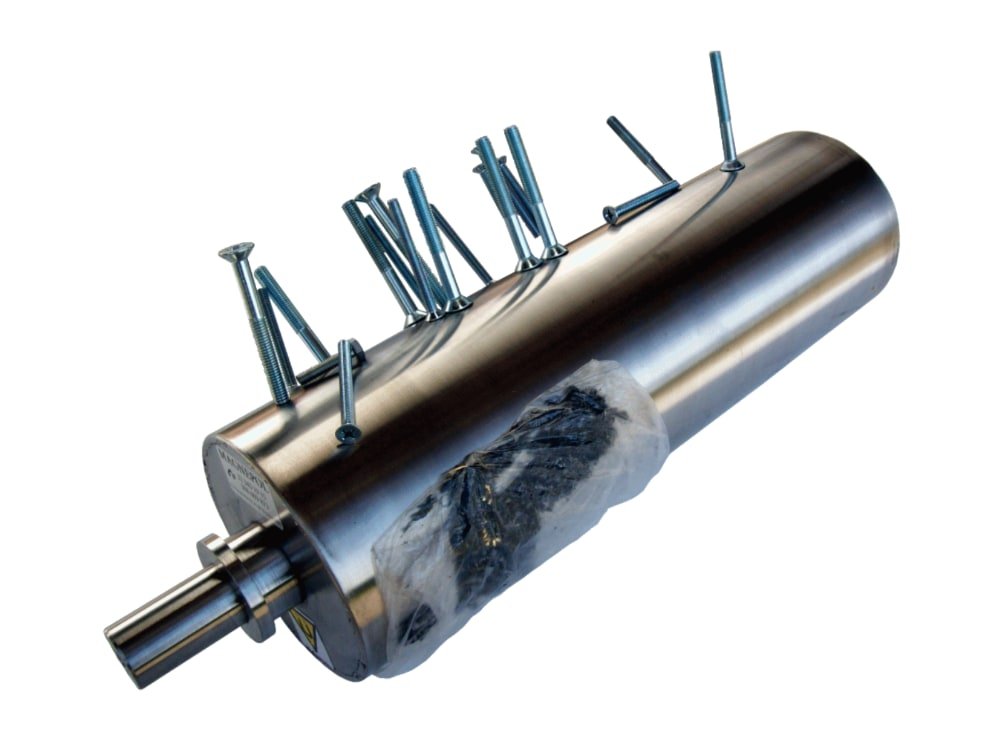

They are most often installed at the ends of conveyor belts, where they are used to catch unwanted ferrous impurities such as screws, filings, wires and machine parts.

The magnetic roller cover rotates with the belt, while the active magnetic surface remains static. Steel waste is held by the magnetic field and is "released" after being transported to a safe distance.

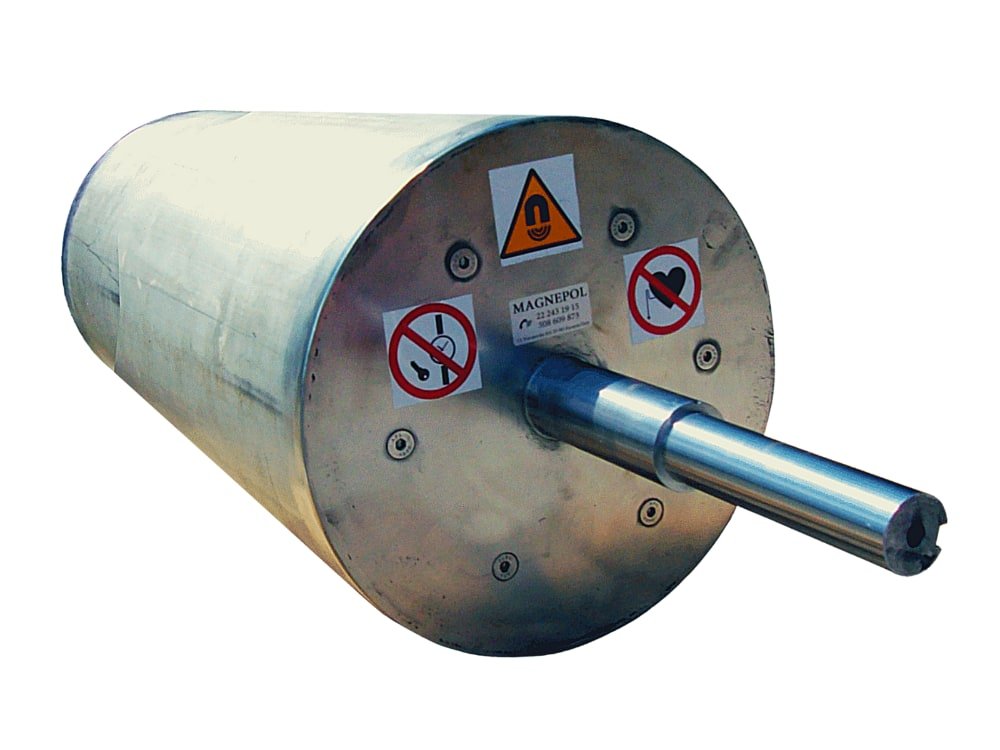

Magnetic rollers are suitable for continuous operation. They are constructed, depending on the application and needs, on the basis of neodymium or ferrite magnets.

Application

Location of the separator

Gravity transport

Conveyor transport

Example application

Magnetic drums are suitable for filtration of any material transported on a conveyor belt

Advantages

Effective filtration across the entire conveyor belt width

Automatic separation of steel particles

Ability to continuous operation

Magnetic roller with 306 mm diameter and 800 mm drum length, made of ferrite magnets

Magnetic roller with 109 mm diameter and 620 mm drum length, made on neodymium magnets

In addition to the standard models available in the online shop, we manufacture customised devices for individual industrial line dimensions.