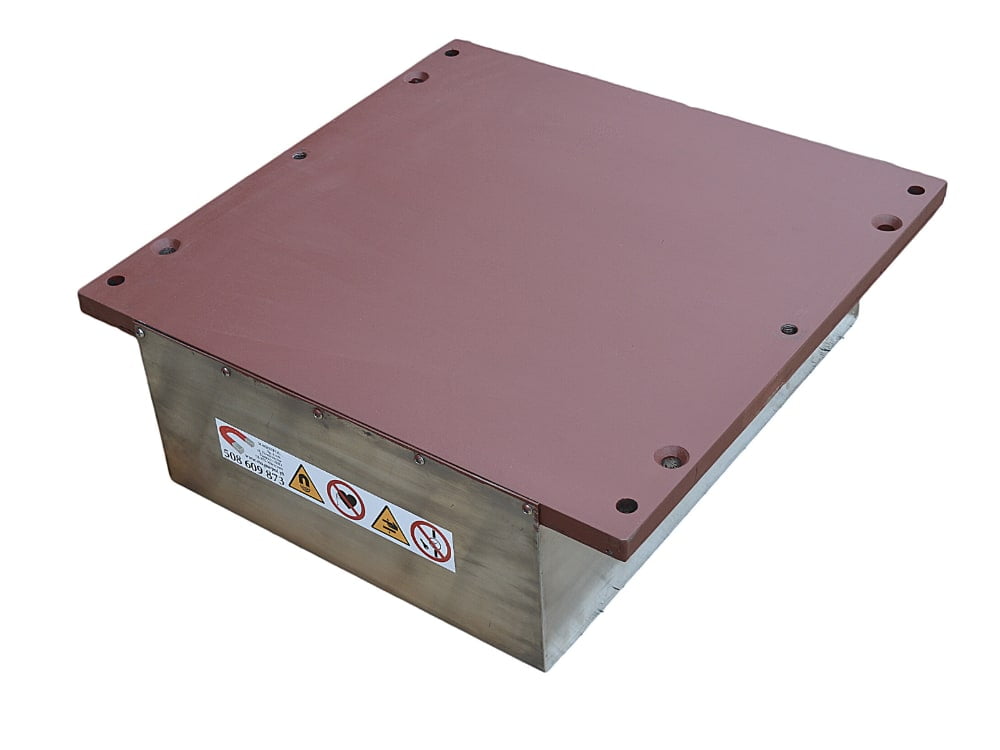

Magnetic plate separators

They are usually installed suspended above the conveyor belt, although they can also be used as chute filters. The magnetically active part is the lower surface of the separator, capturing steel impurities from a long distance. In the upper plate of the separator there are threaded holes or eye bolts, made as assembly parts according to the needs of the customer.

Plate separators are constructed in version based on ferrite magnets and neodymium magnets. Both solutions have their advantages, therefore before choosing a particular model we recommend contacting our expert in order to select an appropriate solution.

For the version installed above the conveyor belt, we also offer an additional self-cleaning mechanism.

Application

Location of the separator

Gravity transport

Conveyor transport

Example application

Filtration of ferrous scrap from aggregates (granite, coal, limestone basalt etc.)

Filtration of wood raw materials

Cement filtration

Filtration in recycling (cullet, plastics etc.)

Filtration in agriculture

Advantages

Easy assembly

High temperature operation for ferrite magnet version

Easy-to-use design

Dustproof

Efficient use on large line widths

Ferrite magnetic plate, 700 mm wide

Ferrite magnetic plate, 1400 mm wide

In addition to the standard models available in the online shop, we manufacture customised devices for individual industrial line dimensions.