Characteristics of separators for loose materials

Separators for loose materials are magnetic devices used to remove small metals from various loose materials. Such contaminants can appear in the process either with the input product or as a result of the gradual wear of parts in the production process. They are widely used in many industries including food, chemicals, ceramics and many others. Good product flow and high magnet strength are important in their work. These two features guarantee the effectiveness of the tasks performed by metal separators.

Types of separators for loose materials:

Separators used for gravity transport

Such separators are used wherever the product is transported by gravity. They are used, for example, in chutes in the production of animal feed. This category includes devices such as: magnetic grates (they operate on the principle of a magnetic sieve or magnetic traps), drum separators (they are usually mounted at the ends of conveyor belts and are used to capture iron impurities), conical magnetic separators (they are used in pipelines, gravity chutes) and pneumatic installations), drawer magnetic separators (here, the magnetically active elements are rollers, which can be arranged in a drawer in 1 to 4 levels).

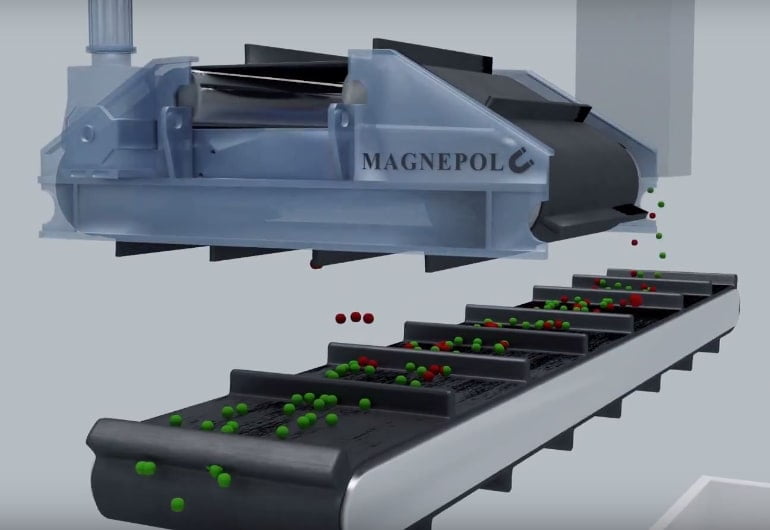

Separators used in conveyor transport

They are used to separate metal impurities from goods transported on belt conveyors. These can be magnetic beams that are mounted above the conveyors and catch even the smallest metals from the transported raw materials, plate magnetic separators that are used to catch thicker iron elements, magnetic threshold separators, as well as magnetic rollers - used in conveyor belts.

Separators used in pressure transport

They are used to clean raw materials that are transported pneumatically (under pressure and under pressure). They are most often used to clean products such as cereals, flour or sawdust. Magnetic separators of this type are mounted in the middle of the free flow of the raw material, which guarantees effective product cleaning.